Services and special features

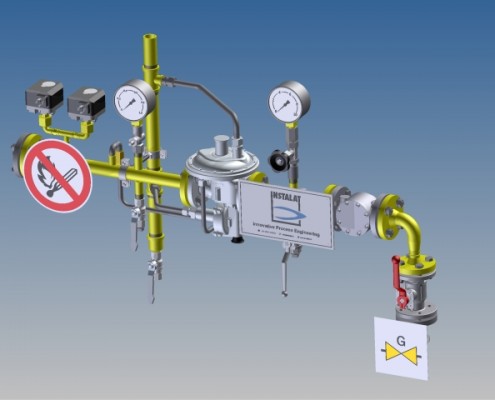

Instalat employs specialized and certified welding and installation engineers.

That is the reason why we are able to cover all works in the field of gas installation technology.

We can also supply the right personnel to fulfill all inspection works on periodic basis when obliged by governmental laws and environmental prescriptions.

Instalat also supplies several services to its clients.:

- Periodic maintenance for firing equipments including associated reports

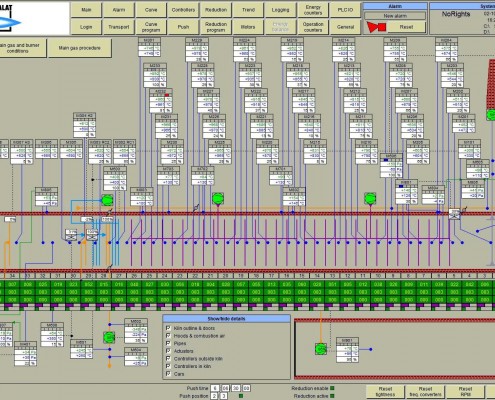

- Remote service for PLC controlled equipments

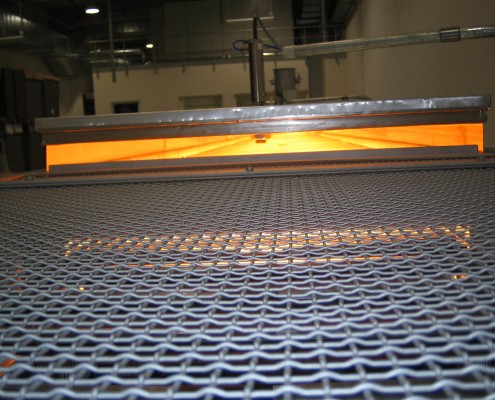

- Start up and commissioning of kilns

- Thorough investigations on existing kilns with Datapaq curves, heat balances and associated reports